Introduction: In an era defined by digital immediacy, it’s a paradox that many businesses still manage their most critical physical assets with tools from the past. Stacks of paper forms, cryptic sticky notes, scattered spreadsheets, and voicemail tag are the silent profit killers in countless maintenance departments. While this might seem manageable for a very small operation, it quickly becomes a significant competitive disadvantage. The truth is, manual work order management isn’t just inefficient; it’s an operational drag that directly erodes productivity, inflates costs, and keeps valuable business intelligence locked away in filing cabinets. It’s time to stop the paper chase and embrace a solution built for the modern world.

The Hidden Costs of Manual Work Orders (The «Before»)

Relying on paper and spreadsheets is more than just an inconvenience; it carries substantial hidden costs that impact your entire operation.

- The Productivity Drain: Manual processes are inherently slow. A technician fills out a form, it gets handed to a manager, it’s manually entered into a spreadsheet (maybe), and if information is missing or handwriting is illegible, the cycle of phone calls and emails begins. All this administrative friction steals precious time from value-adding work.

- The High Price of Human Error: Every manual hand-off or data entry point is a potential for error. A lost work order, a misread instruction, or an incomplete request can lead to incorrect repairs, wasted parts, and even safety risks.

- The Black Hole of Asset History: Once a paper work order is completed, where does it go? Often, it’s filed away and forgotten, or simply discarded. This creates a «data black hole.» Without an accessible, long-term history for each asset, it’s impossible to spot recurring issues, analyze trends, or make informed, data-driven decisions about major repairs or replacements.

- The Communication Bottleneck: When a manager or department head needs a status update on a critical repair, manual systems offer no immediate answers. This triggers a disruptive chain of follow-ups, pulling people away from their tasks and creating frustration.

The Digital Advantage: A New Era of Maintenance Efficiency (The «After»)

Transitioning to a digital work order management system, often as part of a CMMS (Computerized Maintenance Management System), directly solves these problems and unlocks a new level of performance.

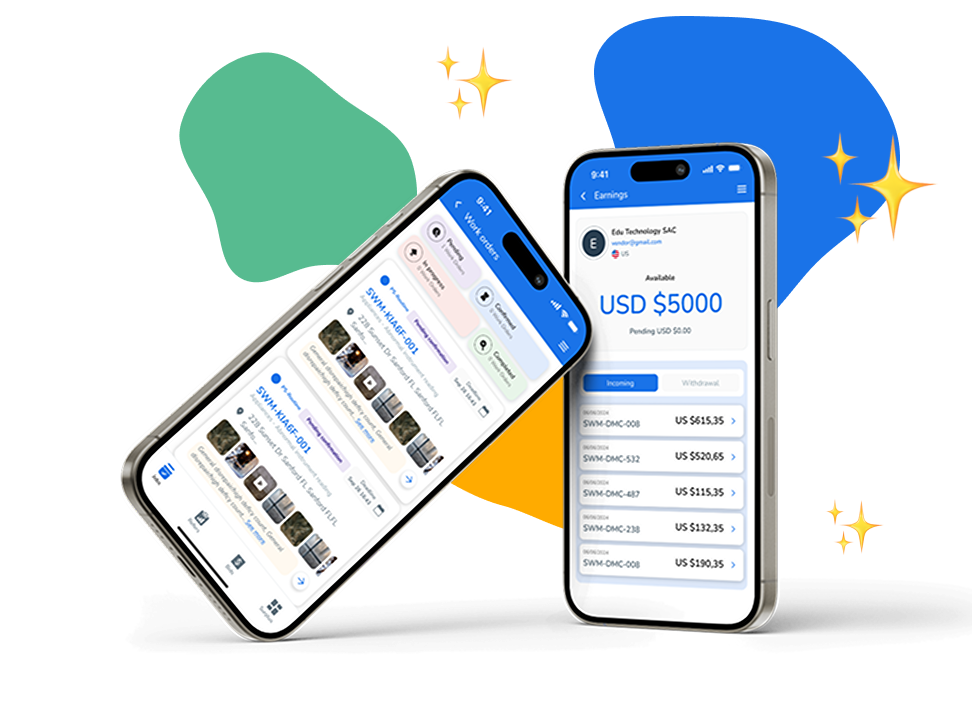

- Streamlined Workflows from Request to Completion: Digital systems automate the entire lifecycle of a work order. With a few clicks, a request can be created, automatically assigned to the right technician with all necessary information, and tracked in real-time through to completion.

- A Foundation of Accurate, Centralized Data: By eliminating manual entry, digital systems ensure data is accurate and consistent. All information is stored in a single, centralized platform, creating a reliable source of truth for reporting and analysis.

- Data-Driven Asset Intelligence: Every completed digital work order contributes to a rich, searchable history for each asset. This lifecycle data is invaluable for predictive maintenance, optimizing PM schedules, and making strategic decisions that extend asset lifespan and maximize value.

- Real-Time Collaboration and Visibility: Digital platforms provide instant visibility for everyone. Technicians can share updates, photos, and notes from the field using mobile devices. Managers can view the status of all work orders on a single dashboard, eliminating the need for constant follow-ups.

Analysis Results: The Quantifiable Impact of Digitization

The shift from manual to digital isn’t just about convenience; it delivers measurable results that directly impact the bottom line. Industry analysis and case studies consistently show significant improvements:

- Increased Technician Productivity: By automating administrative tasks and eliminating wasted time searching for information, companies typically report a 20-30% increase in productive «wrench time» for their maintenance teams.

- Reduced Equipment Downtime: With better planning, faster response times, and data-driven preventive maintenance, businesses often see a reduction in unplanned equipment downtime of 25% or more.

- Extended Asset Lifespan: Access to complete asset histories allows for smarter maintenance strategies, which can extend the operational life of critical equipment by up to 20%, delaying major capital expenditures.

- Drastic Reduction in Administrative Overhead: The time spent on creating, distributing, tracking, and filing paper work orders is nearly eliminated, freeing up managers and technicians to focus on strategic tasks.

- Positive Return on Investment (ROI): When factoring in reduced downtime, lower repair costs, increased productivity, and longer asset life, the investment in a digital work order system typically yields a positive ROI within the first 6-12 months.

Choosing Your Digital Toolkit: A 5-Step Guide to the Right System

Selecting the right digital system is crucial. Follow this simple guide to make an informed choice.

- Define Your Core Needs: First, identify your biggest pain points. Do you need better tracking, mobile access for technicians, or powerful reporting? A clear list of requirements is your most important tool.

- Prioritize User Experience: The best system is one your team will actually use. Look for a clean, intuitive interface that requires minimal training. A user-friendly design ensures rapid adoption and reduces resistance to change.

- Verify Integration and Scalability: Ensure the system can integrate with other software you use (like ERP or accounting systems) and that it can scale with your business as you add more assets and users.

- Assess Mobile Capabilities: In today’s work environment, a powerful mobile app is non-negotiable. Your team needs to be able to access, update, and complete work orders from anywhere on their smartphones or tablets.

- Evaluate Vendor Reputation and Support: Research the vendor’s track record through customer reviews and case studies. Ensure they provide excellent training, technical assistance, and ongoing support to guarantee a smooth implementation.

Conclusion: A Strategic Imperative for Growth The era of managing critical maintenance with paper and spreadsheets is over. Adopting a digital work order management system is no longer just an option for improvement—it’s a strategic imperative for any business looking to enhance efficiency, reduce costs, and stay competitive. It’s time to step into the future, leaving the limitations of the past behind and embracing the precision, intelligence, and profitability of a fully digitized maintenance operation.